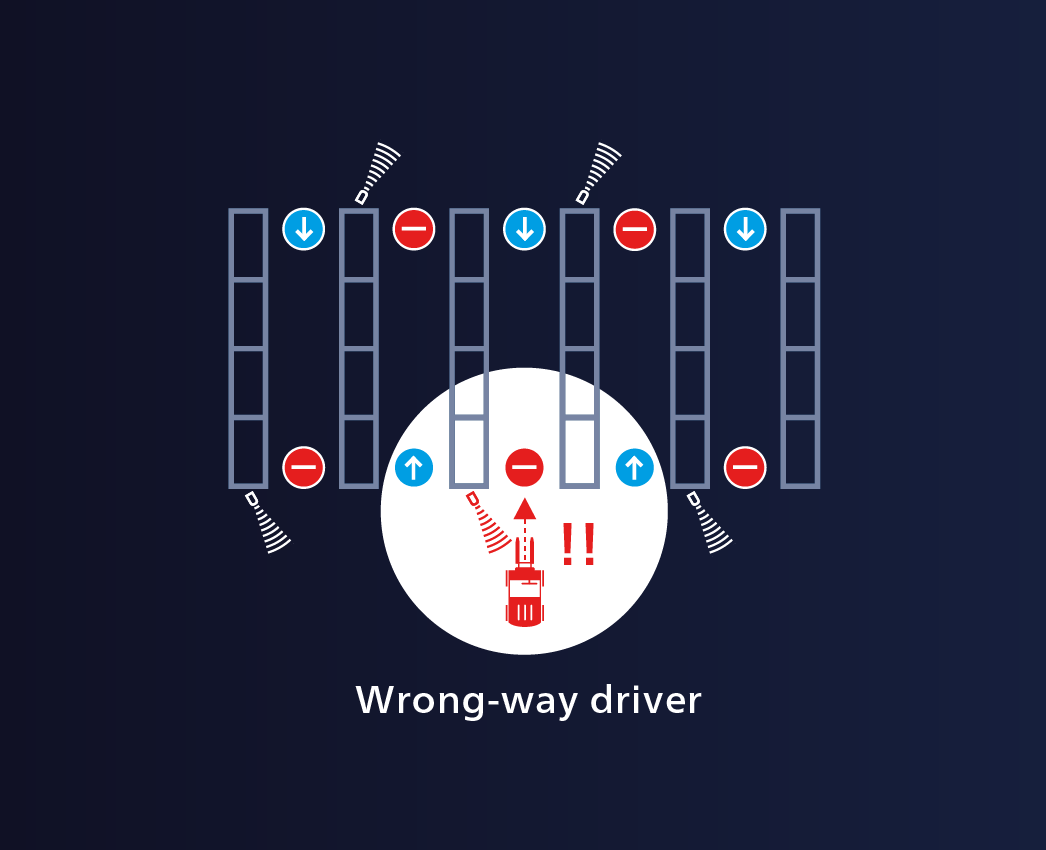

The new Wrong-way sensor

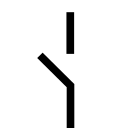

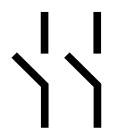

guides factory trucks safely and accident-free through high-bay warehouses. To do this, the sensor detects incoming and outgoing industrial trucks in rack aisles. At the same time, the wws detects the direction of travel of the incoming and outgoing factory trucks.

Detects direction and entry to area

When the one-way street rule is set in the high-bay warehouse, factory trucks that enter the rack aisle in the correct direction of travel should not be warned. However, if a factory truck enters the rack aisle in the wrong direction, the driver should be warned acoustically and visually. To do this, the wrong-way sensor is equipped with a flash light and a horn. This is to avoid unnecessary wrong entries and collisions with oncoming factory truck.