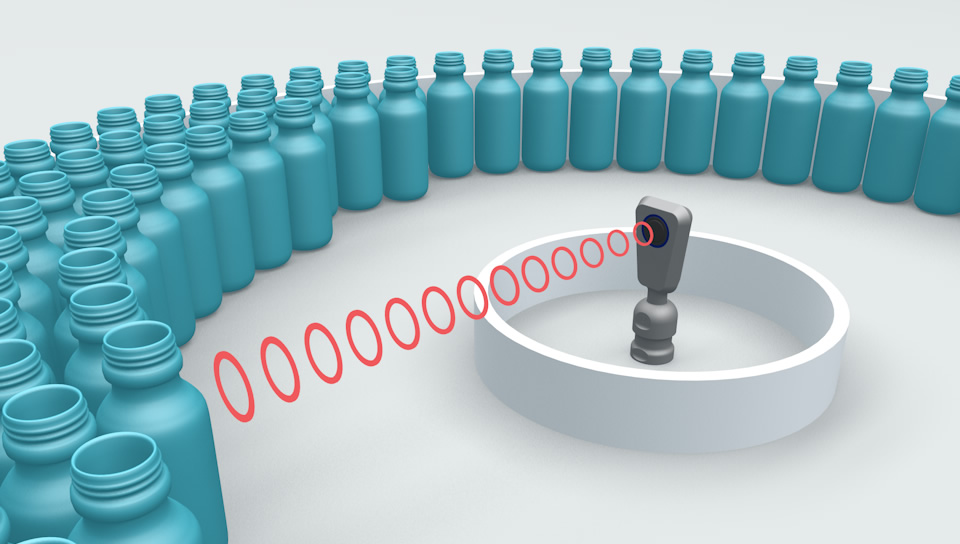

The pms ultrasonic sensors

are designed for the most demanding hygienic requirements according to EHEDG guidelines. Two versions of the sensor are available: D12 adapter shaft and D12 bayonet catch. The standard version D12 adapter shaft is mounted with a hygienic screw connection BF-pms/A1 or an adequate mounting clip.

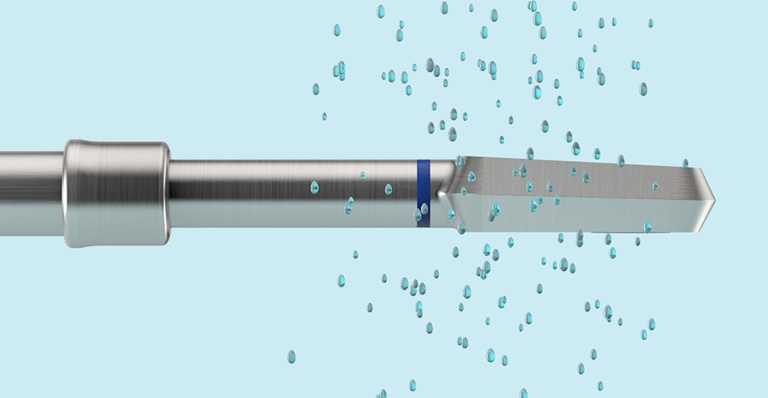

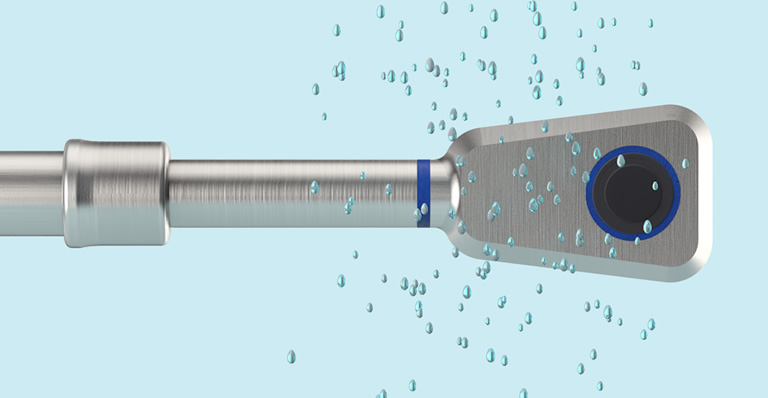

The innovative design of the stainless steel housing ensures that the pms sensor has no horizontal surfaces in almost all conceivable installation positions. Even with horizontal installation of the hygienic sensor for measuring vertical downwards, the rear side of the housing maintains an angle of ≥ 3°. Cleaning fluids can safely drain off the housing.

Rear side of the housing with an incline of ≥ 3°

The smooth stainless steel housing has a roughness depth of Ra < 0.8 µm and has no crevices and dirt edges. Besides the sensor design, the right material is crucial. The ultrasonic transducer is protected by a PTFE foil and withstands chemically aggressive cleaning agents and disinfectants. The pms has a high endurance and is ECOLAB certified.

Stainless-steel sensor in wash-down design, all horizontal surfaces are at least inclined by 3°

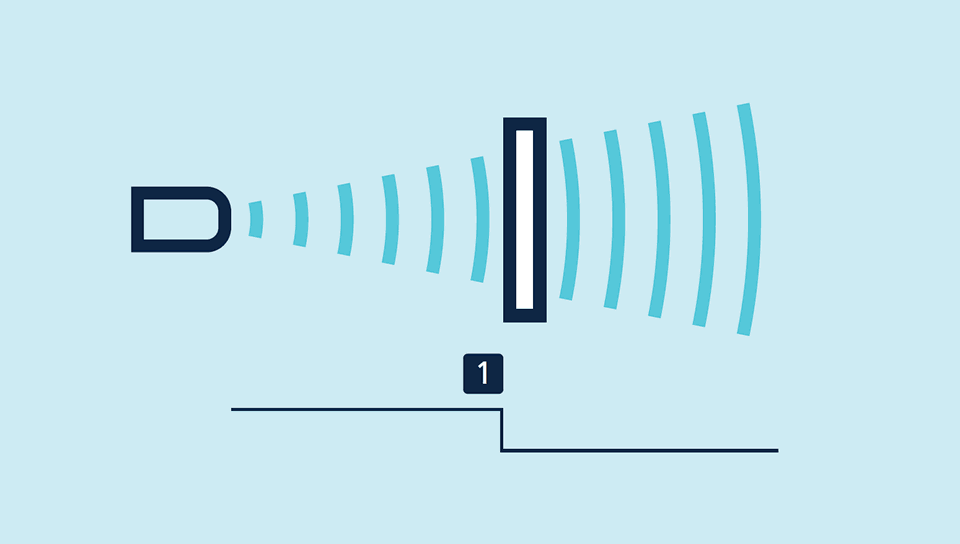

For the pms hygiene sensors

there are 2 output stages and 4 detection ranges available:

|

1 Push-Pull switching output with pnp or npn switching technology |

|

1 analogue output 4–20 mA or 0–10 V |