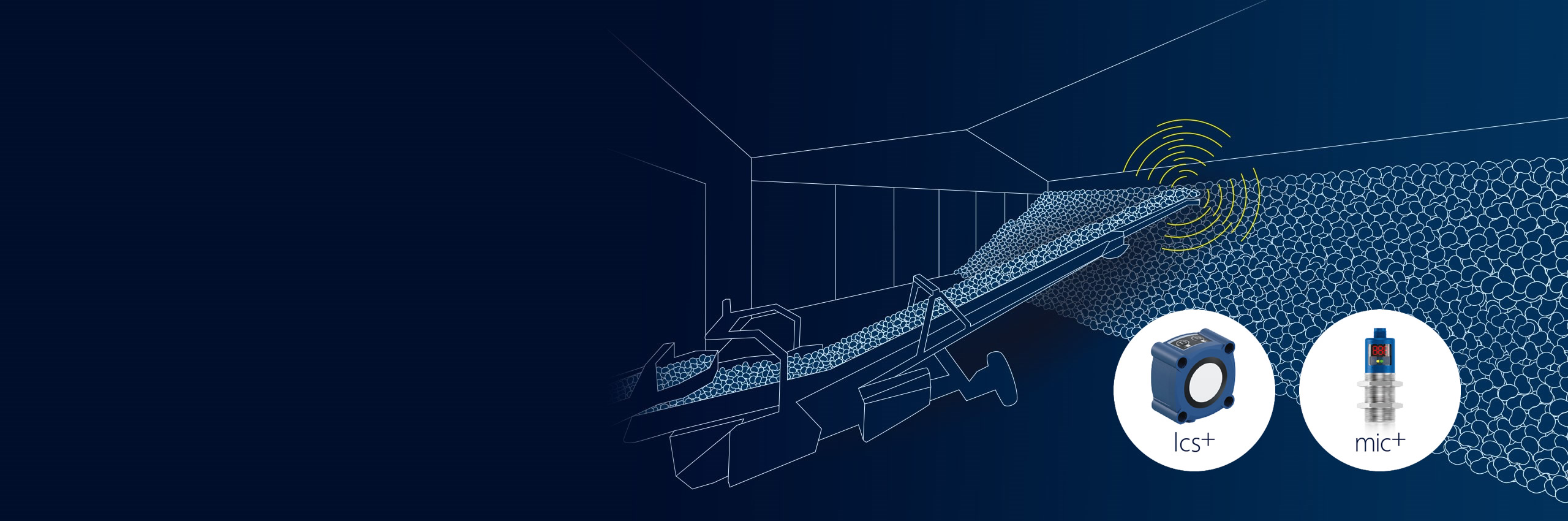

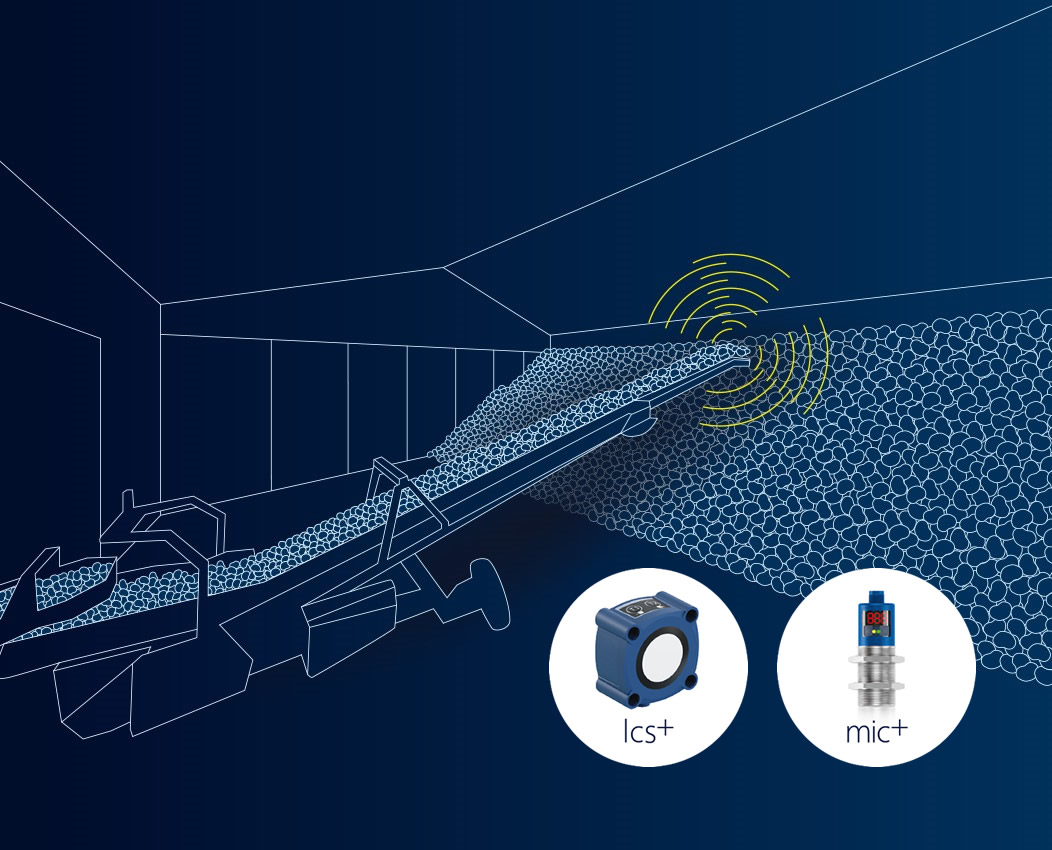

From the field to the shelf: microsonic ultrasonic sensors convince when used in both field and orchard-based harvesting applications and automated livestock farming.

Our ultrasonic sensors help farmers to sow and plant exactly. Fertilize fields and orchards with the highest accuracy and then harvest the crop precisely and safely.