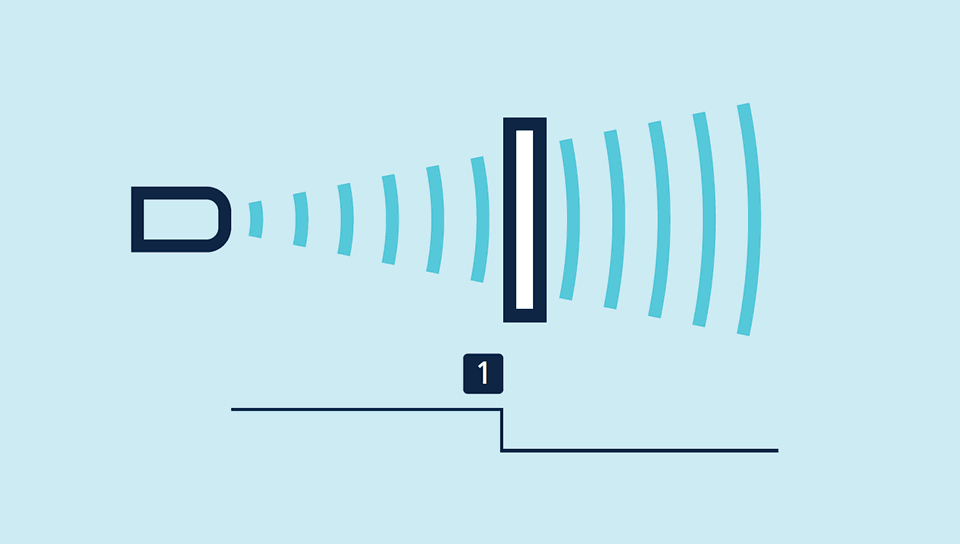

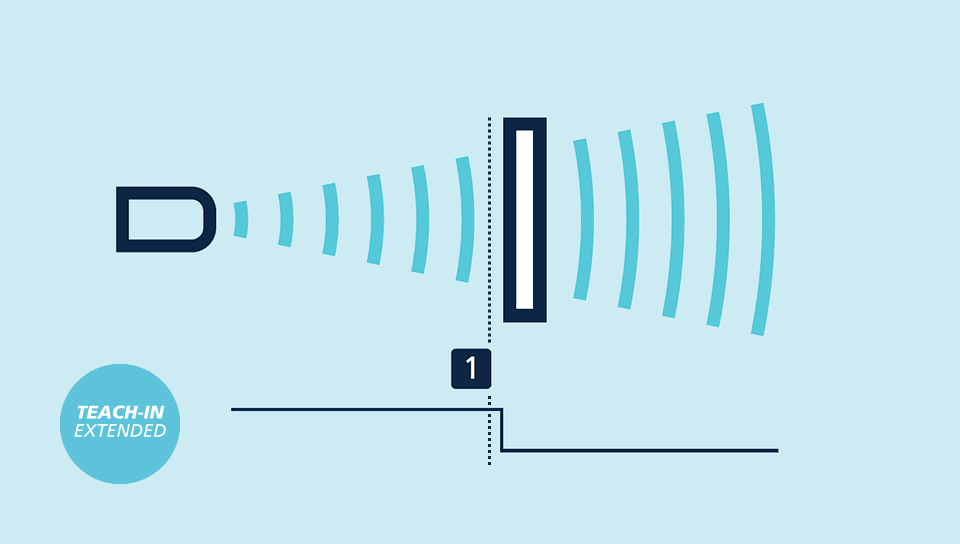

For configuration of a window

with two switching points on a single switching output, the procedure is the same as setting the analogue characteristic.

Analogue sensors

check the connected working resistance at the output and automatically switch to 4–20 mA current output or 0–10 V voltage output.

NCC/NOC

and rising/falling analogue characteristics can also be set via the buttons.

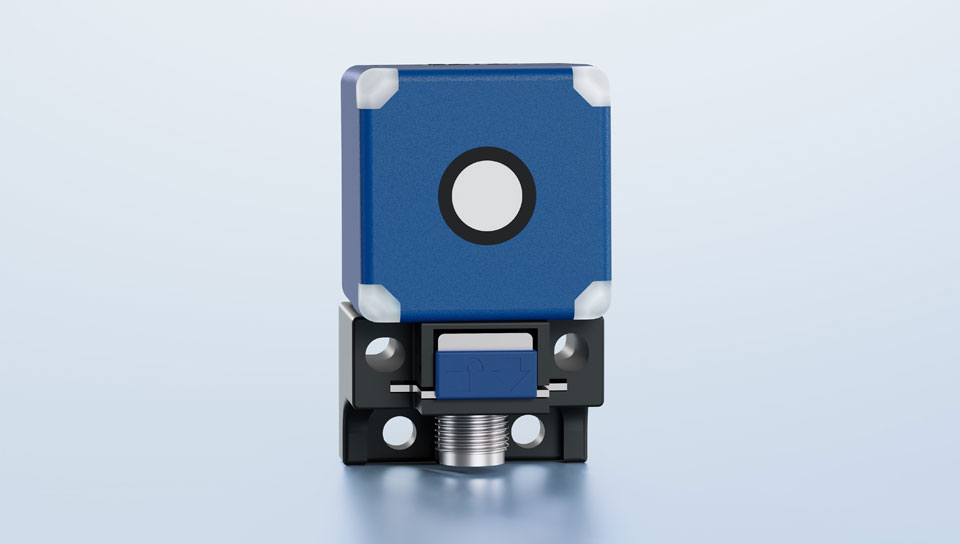

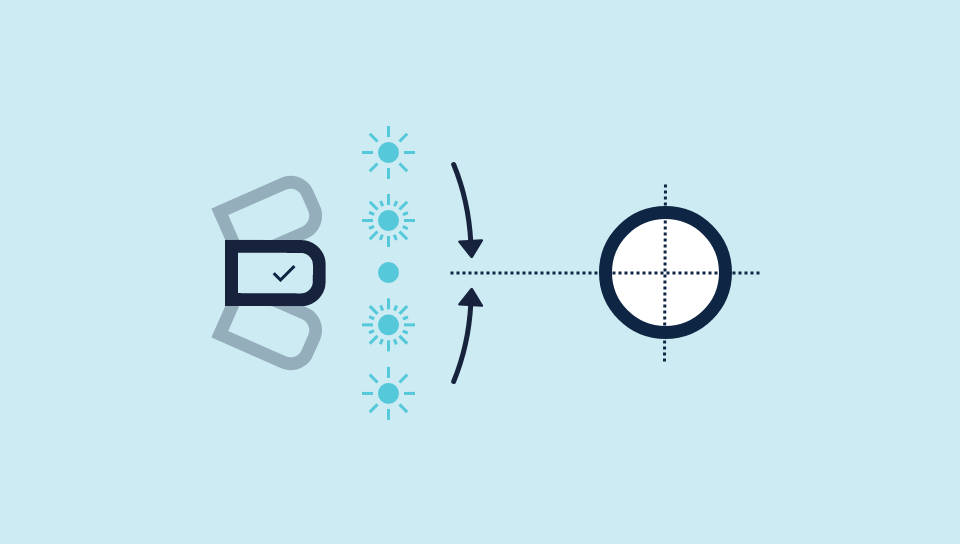

LinkControl

permits comprehensive parameterisation of cube ultrasonic sensors via the LinkControl-Adapter LCA-2 which connects the sensors to the PC.

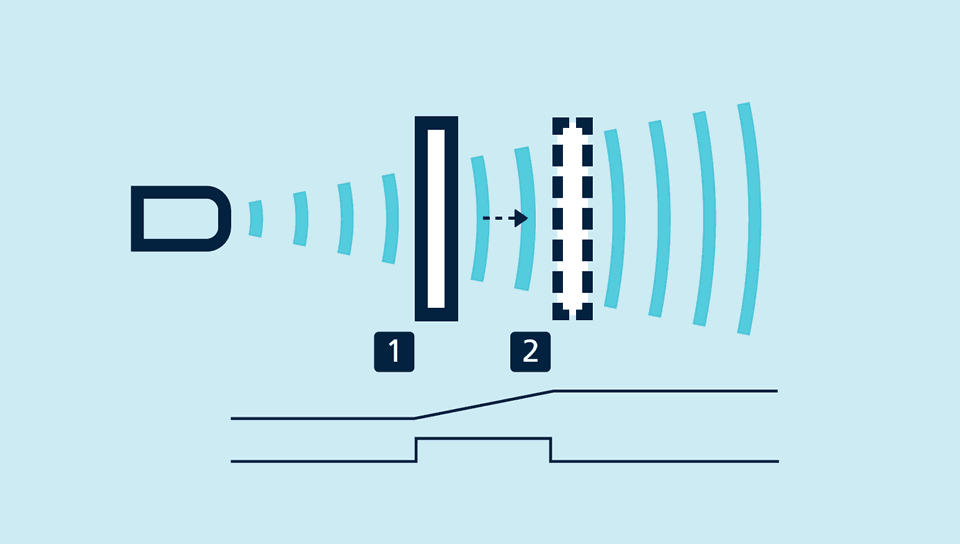

Sensor connected to the PC via LCA-2 for programming

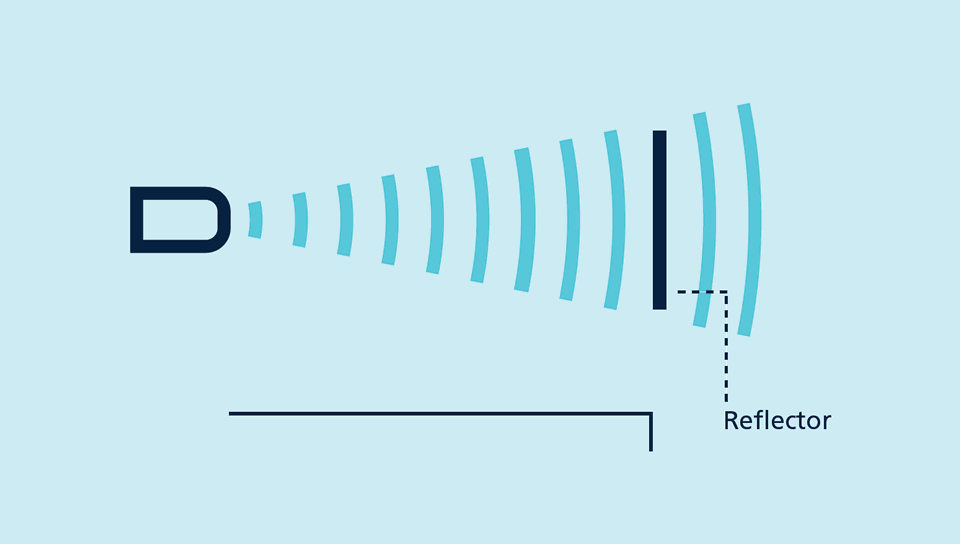

Easy to synchronise

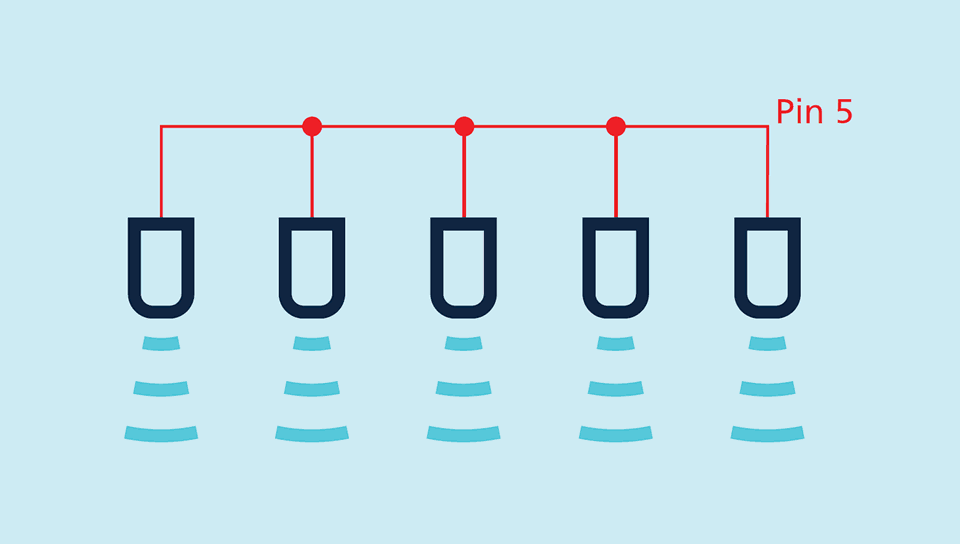

If several cube ultrasonic sensors are operated in one application, the can be synchronised via pin 5 to prevent.

Synchronisation über Pin 5

If more than 10 sensors must be synchronised, this can be carried out with the SyncBox1, which is available as an accessory. Synchronisation via pin 5 is also possible in IO-Link mode.